Structural features

Triple eccentric, double eccentric structure, effectively reduce the friction between the sealing pair of butterfly valve, greatly improve the service life of the valve;The butterfly valve adopts "J" type RPTFE valve seat after development and improvement. It has good elasticity and long service life, and can automatically compensate the change of temperature and pressure, as well as the sealing compensation of wear and tear due to long-term use of the switch.At the same time, under the action of the medium force, always maintain reliable sealing performance;Ultra-low friction coefficient self-lubricating shaft sleeve, reduce the friction between the stem and sleeve, so that the butterfly valve more easily open and close;The "tangential pin" connection between the valve stem and butterfly plate effectively increases the strength of the valve stem and reliability of the connection between the valve stem and butterfly plate;Special floating valve seat design, according to the direction of the pressure source, automatically adjust the seat position, so that the valve in the full close position has the ideal sealing specific pressure, achieve the valve double-side pressure, and extend the service life of the valve seat, increase the possibility of the valve service life up to a million times;It has a flight-proof structure to ensure that the stem does not fall out of the valve due to the failure of the connection between the stem and the disc;ISO5211 top flange design can be connected with various electric, pneumatic, manual and other intelligent driving devices;ANSI/FCI70-2 specifies leak levels and test procedures for control valves;High performance butterfly valve can achieve the bubble free seal as stipulated in MSS-SP61, that is, higher than class VI;Easy maintenance, manufacturing process optimization, increase the replacement of parts;Damage to valve shaft and disc can be replaced directly on the spot. Comprehensive maintenance can be carried out only with general manual tools.The whole series of high performance butterfly valves can provide customers with different materials according to their different working conditions.

Executive Standards

Design and manufacturing: GB/T12238, API609, EN593, etc

API609, EN558, ISO5752, etc

Connecting flange: GB/T9113, DIN1092-1. ASME B16.5 ᵣ and etc

Inspection test: GB/T13927, API598, EN12266.1, etc

Performance parameter

Nominal diameter: DN50 ~ 600mm NPs 2 "~ 24"

Nominal pressure: PN2.5 ~ 40 Class 150 ~ 300lb

Applicable temperature: 150 ℃

Connection mode: clamp type, lug type, flange type, etc

Driving mode: handle, worm gear drive, electric, pneumatic, etc

Main materials: carbon steel, austenitic stainless steel, duplex stainless steel, copper alloy, titanium alloy and various special materials

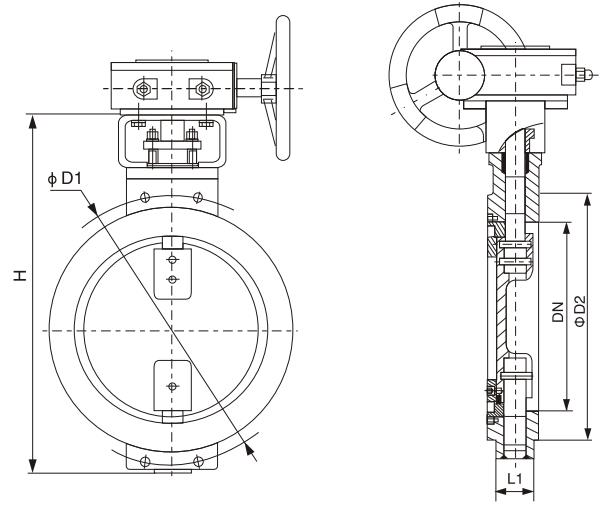

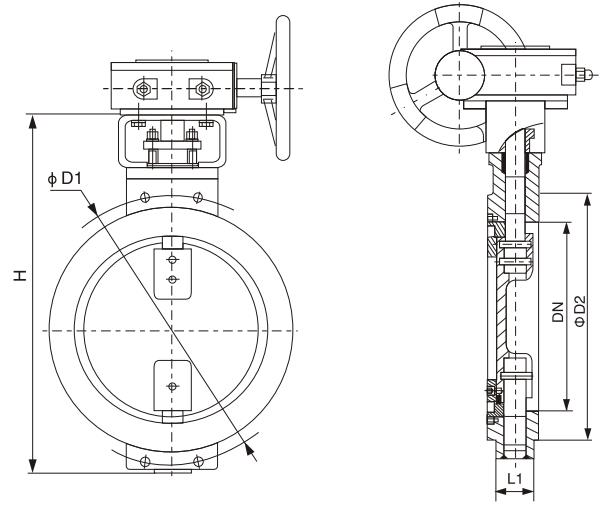

Product size

|

DN

|

150Lb

|

|

In

|

mm

|

L

|

L1

|

L2

|

L3

|

D

|

D1

|

D2

|

C

|

H

|

N-d

|

|

3

|

80

|

114

|

48

|

180

|

48

|

190

|

152.4

|

127

|

24.3

|

310

|

4-19

|

|

4

|

100

|

127

|

54

|

190

|

54

|

230

|

190.5

|

157

|

24.3

|

325

|

8-19

|

|

5

|

125

|

140

|

56

|

200

|

56

|

255

|

215.9

|

186

|

24.3

|

360

|

8-22

|

|

6

|

150

|

140

|

57

|

210

|

57

|

280

|

241.3

|

216

|

26.9

|

395

|

8-22

|

|

8

|

200

|

152

|

64

|

230

|

64

|

345

|

298.5

|

270

|

29

|

480

|

8-22

|

|

10

|

250

|

165

|

71

|

250

|

71

|

405

|

362.0

|

324

|

30.6

|

550

|

12-26

|

|

12

|

300

|

178

|

81

|

270

|

81

|

485

|

431.8

|

381

|

32.2

|

610

|

12-26

|

|

14

|

350

|

190

|

92

|

290

|

92

|

535

|

476.3

|

413

|

35.4

|

710

|

12-29

|

|

16

|

400

|

216

|

102

|

310

|

102

|

595

|

539.8

|

470

|

37

|

755

|

16-29

|

|

18

|

450

|

222

|

114

|

330

|

114

|

635

|

577.9

|

533

|

40.1

|

835

|

16-32

|

|

20

|

500

|

229

|

127

|

350

|

127

|

700

|

635.0

|

584

|

43.3

|

900

|

20-32

|

|

24

|

600

|

267

|

154

|

390

|

154

|

815

|

749.3

|

692

|

48.1

|

1060

|

20-35

|

|

28

|

700

|

292

|

165

|

430

|

165

|

925

|

863.6

|

800

|

71.9

|

1170

|

28-35

|

|

32

|

800

|

318

|

190

|

470

|

190

|

1060

|

977.9

|

914

|

81.4

|

1320

|

28-41

|

|

36

|

900

|

330

|

203

|

510

|

203

|

1170

|

1085.8

|

1022

|

90.9

|

1440

|

32-41

|

|

40

|

1000

|

410

|

216

|

550

|

216

|

1290

|

1200.2

|

1124

|

90.9

|

1640

|

36-41

|

|

48

|

1200

|

470

|

254

|

630

|

254

|

1510

|

1422.4

|

1359

|

108.4

|

1850

|

44-41

|

|

56

|

1400

|

530

|

390

|

710

|

390

|

1745

|

1651.0

|

1575

|

124.3

|

2040

|

48-48

|

|

DN

|

300Lb

|

|

In

|

mm

|

L

|

L1

|

L2

|

L3

|

D

|

D1

|

D2

|

C

|

H

|

N-d

|

|

3

|

80

|

180

|

48

|

180

|

48

|

210

|

168.3

|

127

|

29

|

310

|

8-22

|

|

4

|

100

|

190

|

54

|

190

|

54

|

255

|

200.0

|

157

|

32.2

|

325

|

8-22

|

|

5

|

125

|

200

|

56

|

200

|

56

|

280

|

235.0

|

186

|

35.4

|

360

|

8-22

|

|

6

|

150

|

210

|

59

|

210

|

59

|

320

|

269.9

|

216

|

37

|

430

|

12-22

|

|

8

|

200

|

230

|

73

|

230

|

73

|

380

|

330.2

|

270

|

41.7

|

535

|

12-26

|

|

10

|

250

|

250

|

83

|

250

|

83

|

445

|

387.4

|

324

|

48.1

|

695

|

16-29

|

|

12

|

300

|

270

|

92

|

270

|

92

|

520

|

450.8

|

381

|

51.3

|

805

|

16-32

|

|

14

|

350

|

290

|

117

|

290

|

117

|

585

|

514.4

|

413

|

54.4

|

880

|

20-32

|

|

16

|

400

|

310

|

133

|

310

|

133

|

650

|

571.5

|

470

|

57.6

|

930

|

20-35

|

|

18

|

450

|

330

|

149

|

330

|

149

|

710

|

628.6

|

533

|

60.8

|

990

|

24-35

|

|

20

|

500

|

350

|

159

|

350

|

159

|

775

|

685.8

|

584

|

64

|

1050

|

24-35

|

|

24

|

600

|

390

|

181

|

390

|

181

|

915

|

812.8

|

692

|

70.3

|

1230

|

24-41

|

|

DN

|

600Lb

|

|

In

|

mm

|

L

|

L1

|

L2

|

L3

|

D

|

D1

|

D2

|

C

|

H

|

N-d

|

|

6

|

150

|

210

|

78

|

210

|

78

|

355

|

292.1

|

216

|

54.7

|

425

|

12-29

|

|

8

|

200

|

230

|

102

|

230

|

102

|

420

|

349.2

|

270

|

62.6

|

640

|

12-32

|

|

10

|

250

|

250

|

117

|

250

|

117

|

510

|

431.8

|

324

|

70.5

|

745

|

16-35

|

|

12

|

300

|

270

|

140

|

270

|

140

|

560

|

489

|

381

|

73.7

|

820

|

20-35

|

|

14

|

350

|

290

|

155

|

290

|

155

|

605

|

527

|

413

|

76.9

|

935

|

20-38

|

|

16

|

400

|

310

|

178

|

310

|

178

|

685

|

603.2

|

470

|

83.2

|

975

|

20-41

|

|

18

|

450

|

330

|

200

|

330

|

200

|

745

|

654

|

533

|

89.6

|

1110

|

20-45

|

|

20

|

500

|

350

|

216

|

350

|

216

|

815

|

723.9

|

584

|

95.9

|

1215

|

24-45

|

|

24

|

600

|

390

|

232

|

390

|

232

|

940

|

838.2

|

692

|

108.6

|

1300

|

24-51

|

|

DN

|

900Lb

|

|

In

|

mm

|

L

|

L1

|

L2

|

L3

|

D

|

D1

|

D2

|

C

|

H

|

N-d

|

|

6

|

150

|

225

|

104

|

225

|

104

|

380

|

317.5

|

216

|

62.6

|

525

|

12-32

|

|

8

|

200

|

275

|

112

|

275

|

112

|

470

|

393.7

|

270

|

70.5

|

660

|

12-38

|

|

10

|

250

|

325

|

135

|

325

|

135

|

545

|

469.9

|

324

|

76.9

|

735

|

16-39

|

|

12

|

300

|

375

|

170

|

375

|

170

|

610

|

533.4

|

381

|

86.4

|

820

|

20-39

|

|

14

|

350

|

425

|

173

|

425

|

173

|

640

|

558.8

|

413

|

92.8

|

870

|

20-41

|

|

16

|

400

|

475

|

210

|

475

|

210

|

705

|

616

|

470

|

95.9

|

965

|

20-45

|

|

18

|

450

|

500

|

228

|

500

|

228

|

785

|

685.8

|

533

|

108.6

|

1050

|

20-51

|

|

20

|

500

|

575

|

250

|

575

|

250

|

855

|

749.3

|

584

|

115

|

1175

|

20-54

|

|

24

|

600

|

675

|

275

|

675

|

275

|

1040

|

901.7

|

692

|

146.7

|

1330

|

20-67

|

|

DN

|

1500Lb

|

|

In

|

mm

|

L

|

L1

|

L2

|

L3

|

D

|

D1

|

D2

|

C

|

H

|

N-d

|

|

6

|

150

|

350

|

160

|

350

|

160

|

395

|

317.5

|

216

|

89.6

|

550

|

12-38

|

|

8

|

200

|

400

|

180

|

400

|

180

|

485

|

393.7

|

270

|

99.1

|

690

|

12-45

|

|

10

|

250

|

450

|

200

|

450

|

200

|

585

|

482.6

|

324

|

115

|

780

|

12-50

|

|

12

|

300

|

500

|

230

|

500

|

230

|

675

|

571.5

|

381

|

130.9

|

905

|

16-54

|

|

14

|

350

|

550

|

250

|

550

|

250

|

750

|

635

|

413

|

140.4

|

990

|

16-60

|

|

16

|

400

|

600

|

265

|

600

|

265

|

825

|

704.8

|

470

|

153.1

|

1085

|

16-67

|

|

18

|

450

|

650

|

300

|

650

|

300

|

915

|

774.7

|

533

|

169

|

1180

|

16-73

|

|

20

|

500

|

700

|

340

|

700

|

340

|

985

|

831.8

|

584

|

184.8

|

1290

|

16-80

|

|

24

|

600

|

800

|

400

|

800

|

400

|

1170

|

990.6

|

692

|

210.2

|

1450

|

16-92

|