1. Integral welded ball valve, no external leakage.

2. The valve seat is composed of PTFE sealing ring and spring, which has strong adaptability to the change of pressure and temperature, and will not produce any leakage in the use range.

3. The machining process of the ball is tracked and detected by the advanced computer detector, and the processing density of the sphere is high.

4. The sealing ring is made of c-ptfe with 20% carbon to ensure no leakage.

5. Compared with similar products of the same specification, the valve body is small, light in weight, beautiful in appearance and long in service life.

6. The valve body, ball and side valve body are all made of slotted steel pipe. The valve rod is sealed with double "O-ring" and has the function of anti blowing out.

7. The filter screen is integrated with the ball, and the ball valve of the filter screen is linked in the pipeline, which has the filtering function, which can replace the filter, play a multi-purpose effect of one valve, save the pipeline installation space and operation cost, and prevent the impurities with diameter greater than 4.5mm from passing through.

8. The filter screen is designed with a slope mouth to ensure that the medium can pass through normally and the valve can work normally when the impurity particles are blocked. The pressure relief valve design can adjust the pressure difference between inside and outside the valve body to improve the safety performance of the valve. At the same time, the screw ball valve can be used to replace the pressure relief valve, which is more time-saving, labor-saving, convenient and flexible.

Design specification: API 6D, ASMEB 16.34

Pressure - temperature classes: ASME B16.34, API608

Structure length: ASME B16.10, GB12221

Butt welding form: ASME B16.25, ASME B31.4/31.8

Inspection and test: API 598, API 6D, GB13927

Fire resistance test: API 607, API 6FA

Nominal diameter: dn200-dn350

Nominal pressure: pn1.6-pn6.4mpa

Service temperature: - 29 ℃ ~ 200 ℃

Operation mode: handle, gear, electric, pneumatic handle, gear, electric, pneumatic

Application scope: heating pipe network, sewage treatment, air conditioning pipe network, power plant, oil pipeline and other industrial pipeline fields.

Use medium: water, gas, oil and other non corrosive media

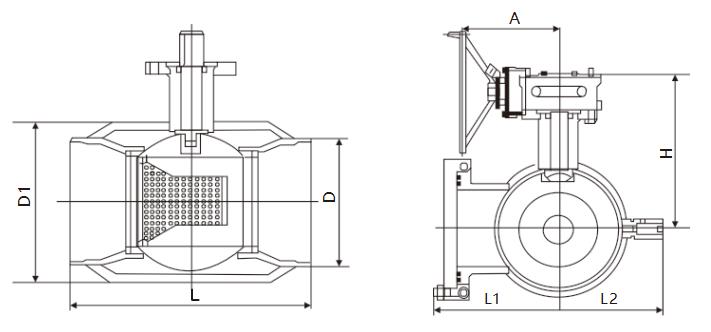

|

DN(mm) |

A |

L |

L1 |

L2 |

D |

D1 |

H |

|

|

GOST |

EN |

|||||||

|

DN200 |

198 |

400 |

270 |

178 |

219.0 |

219.1 |

273 |

318 |

|

DN250 |

225 |

559 |

332 |

222 |

273.0 |

273.1 |

351 |

395 |

|

DN300 |

245 |

635 |

407 |

282 |

323.9 |

323.9 |

425 |

467 |

|

DN350 |

319 |

762 |

455 |

455 |

377.0 |

355.6 |

508 |

540 |